TiAl4822 Powder

|

TiAl4822 Powder

|

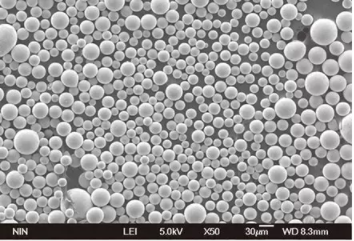

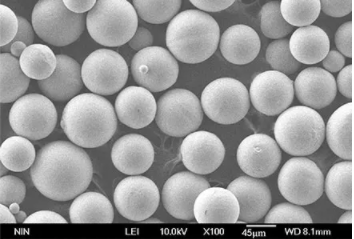

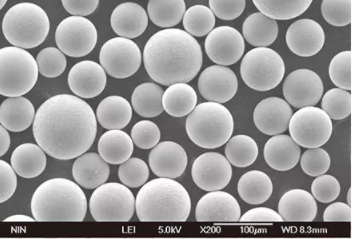

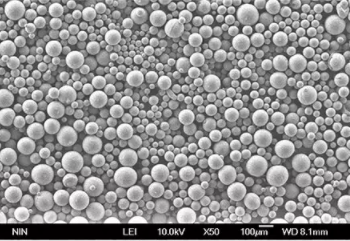

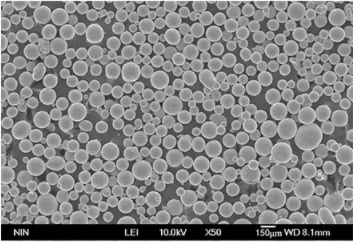

Spherical TiAl4822 alloy powder is prepared by the plasma rotary electrode atomization process. The metal powder has low oxygen content, high sphere rate and good fluidity, the property is very stable, there is almost no hollow powder or satellite powder which can satisfy the different process requirements for the EBM pave powder 3D printing, laser powder coating 3D printing, laser coaxial powder feeding 3D printing, and high-end powder metallurgy.

|

Element |

Ti |

Al |

Nb |

Cr |

O |

N |

Standard |

Bal |

32-34 |

4.2-5.2 |

2.2-3.2 |

0.06-0.12 |

\ |

Tested |

Bal |

33.13 |

4.75 |

2.65 |

0.0846 |

0.0427 |

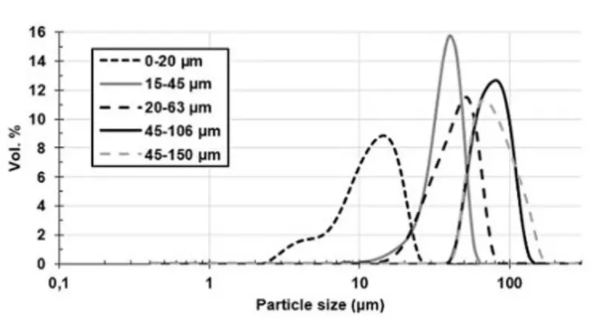

PSD |

10-20um, 15-45um, 20-60um, 45-105um, 45-105um |

Purity |

0.999 |

Sphericity |

>95% |

Bulk Density |

2.22g/cm3 |

Tap Density |

2.51g/cm3 |

Flow Abillity |

18-35s/50g |

Application |

Additive Manufacturing, Laser Cladding, Spraying, PM, HP and etc. |

Standard |

ASTM B348, ASTM F136, ASTM F1580, ASTM F2924, ASTM F3001, AMS 1498 |

Particle Size TiAl4822 Powder

Particle size distribution is measured by laser diffraction as per ASTM B822. Due to the Almost no satellite powder and hollow powder, high sphericity with excellent fluidity, low oxygen content on AM Co., Ltd. powder, the particle size distribution is highly uniform and the D10, D50 and D90 meet and exceed the industry requirements with an exceptional batch to batch reliability. The typical powder of plasma rotary electrode atomized process yield ranges from 0-150 µm, after atomization, the powder is sieved according customer specifications.