Ti Powder

|

Ti Powder

|

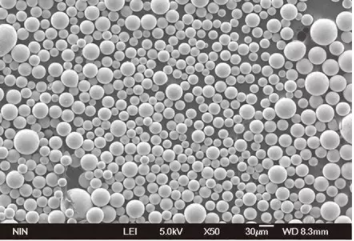

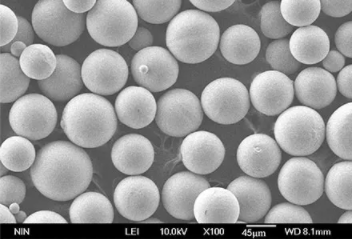

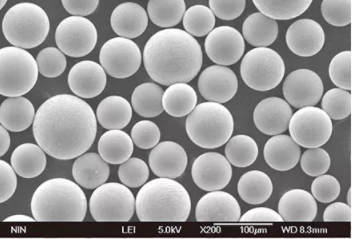

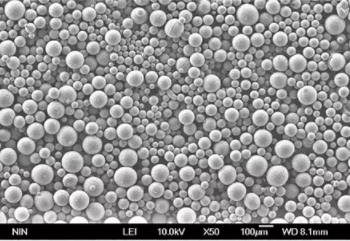

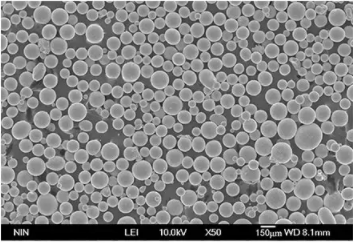

Spherical pure Titanium powder is prepared by the plasma rotary electrode atomized process (PREP). The company focuses on the development and production of high-performance spherical powder products. The high-performance spherical titanium powder and its titanium alloy powder currently produced are international in terms of sphericity, particle size distribution, impurity content, oxygen content, and fluidity. Standard level, can be used in additive manufacturing, powder metallurgy, injection molding, laser repair, cold and thermal spraying and other industries, the application scope involves aerospace, medical and other fields.

|

Element |

Ti |

Al |

Mo |

V |

Cr |

Si |

Fe |

Standard |

Bal |

5.50-7.10 |

0.50-2.0 |

0.80-2.5 |

1.5-2.5 |

≤0.15 |

≤0.25 |

Elements |

C |

N |

H |

O |

O |

O |

O |

Standard |

≤0.08 |

≤0.05 |

≤0.015 |

≤0.15 |

≤0.15 |

≤0.15 |

≤0.15 |

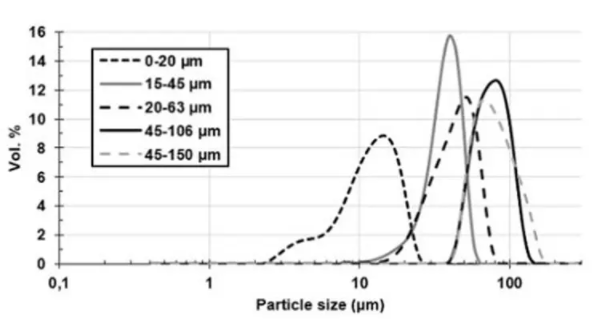

PSD |

0-20um, 15-45um, 20-63um, 45-105um, 45-150um |

Purity |

0.999 |

Oxygen Content |

900-1200ppm |

Sphericity |

>95% |

Flow Ability |

20-35s/50g |

Standard |

ASTM B348, ASTM F136, ASTM F1580, ASTM F2924, ASTM F3001, AMS 1498 |

Particle Size Distribution Ti Powder

Particle size distribution is measured by laser diffraction as per ASTM B822. Due to the Almost no satellite powder and hollow powder, high sphericity with excellent fluidity, low oxygen content on AM Co., Ltd. powder, the particle size distribution is highly uniform and the D10, D50 and D90 meet and exceed the industry requirements with an exceptional batch to batch reliability. The typical powder of plasma rotary electrode atomized process yield ranges from 0-150 µm, after atomization, the powder is sieved according customer specifications.