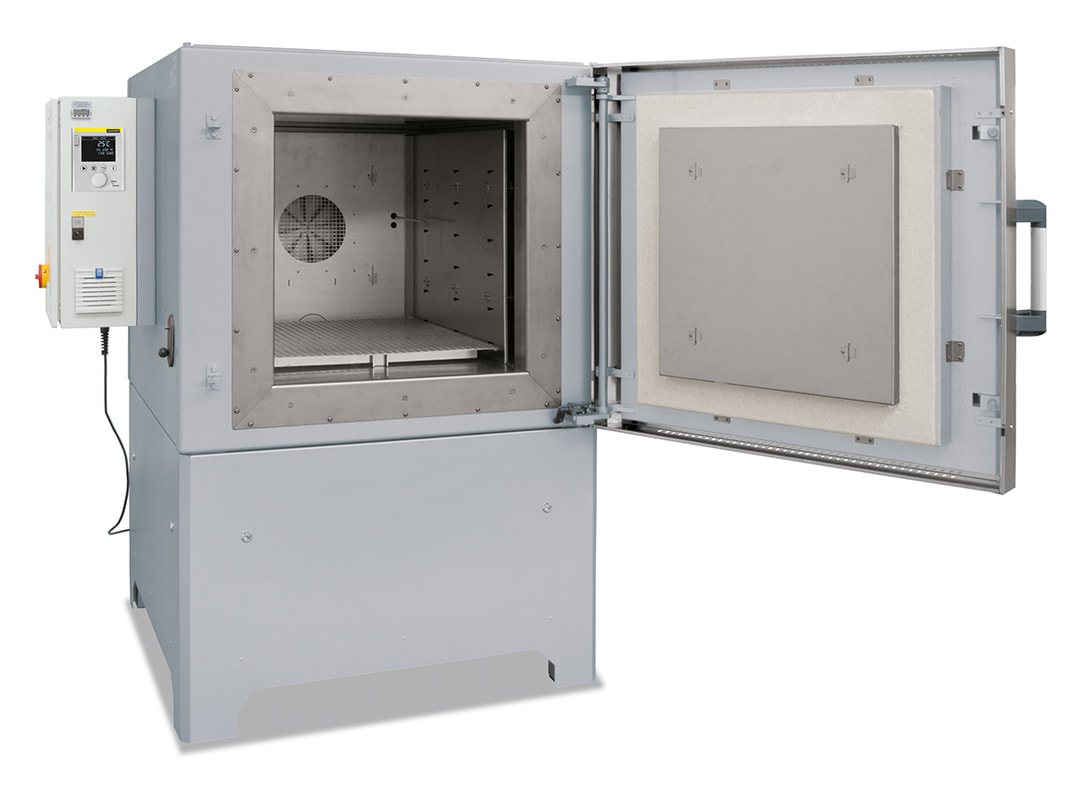

Ovens

Nabertherm Ovens

With their maximum working temperature of up to 300 °C and air circulation, the ovens achieve a perfect temperature uniformity which is much better than in ovens of most competitors. They can be used for various applications such as e.g. drying, sterilizing or warm storing. Ample warehousing of standard models provides for short delivery times.

Model |

Tmax °C |

Inner Dimensions in MM W x D x H |

Outer Dimensions in MM W x D x H |

Volume in l |

Grids Max |

TR 60 |

300 |

450 x 390 x 350 |

700 x 610 x 710 |

60 |

4 |

TR 60 LS |

260 |

450 x 360 x 350 |

700 x 680 x 690 |

57 |

4 |

TR 120 |

300 |

650 x 390 x 500 |

900 x 610 x 860 |

120 |

7 |

TR 120 LS |

260 |

650 x 390 x 500 |

900 x 680 x 840 |

117 |

7 |

TR 240 |

300 |

750 x 550 x 600 |

1000 x 780 x 970 |

240 |

8 |

TR 240 LS |

260 |

750 x 530 x 600 |

1000 x 850 x 940 |

235 |

8 |

TR 450 |

300 |

759 x 550 x 1100 |

1000 x 780 x 1470 |

450 |

15 |

TR 1050 |

300 |

1200 x 670 x 1400 |

1470 x 940 x 1920 |

1050 |

14 |

Nabertherm High-Temperature Ovens, Forced Convection Chamber Furnaces

These chamber furnaces with air circulation are characterized by their extremely high temperature uniformity. Hence, they are especially suitable for processes such as cooling, crystalizing, preheating, curing, but also for numerous processes in tool making. Due to the modular concept, the forced convection furnaces can be adjusted to the process requirements by adding suitable equipment.

Model |

Tmax °C |

Inner Dimensions in MM W x D x H |

Outer Dimensions in MM W x D x H |

Volume in l |

NA 30/45 |

450 |

290 x 420 260 |

1040 x 1290 x 1385 |

30 |

NA 60/45 |

450 |

350 x 500 x 350 |

1100 x 1370 x 1475 |

60 |

NA 120/45 |

450 |

450 x 600 x 450 |

1250 x 1550 x 1550 |

120 |

NA 250/45 |

450 |

600 x 750 x 600 |

1350 x 1650 x 1725 |

250 |

NA 500/45 |

450 |

750 x 1000 x 750 |

1550 x 1900 x 1820 |

500 |

N 15/65 HA |

650 |

395 x 340 x 170 |

470 x 845 x 460 |

15 |

NA 30/65 |

650 |

290 x 420 x 260 |

870 x 1290 x 1385 |

30 |

NA 60/65 |

650 |

350 x 500 x 350 |

910 x 1390 x 1475 |

60 |

NA 120/65 |

650 |

450 x 600 x 450 |

990 x 1470 x 1550 |

120 |

NA 250/65 |

650 |

600 x 750 x 600 |

1170 x 1650 x 1680 |

250 |

NA 500/65 |

650 |

750 x 1000 x 750 |

1290 x 1890 x 1825 |

500 |

N 30/85 HA |

850 |

290 x 420 x 260 |

607 x 1175 x 1315 |

30 |

N 60/85 HA |

850 |

350 x 500 x 350 |

667 x 1250 x 1400 |

60 |

N 120/85 HA |

850 |

450 x 600 x 450 |

767 x 1350 x 1500 |

120 |

N 250/85 HA |

850 |

600 x 750 x 600 |

1002 x 1636 x 1860 |

250 |

N 500/85 HA |

850 |

750 x 1000 x 750 |

1152 x 1886 x 2010 |

500 |

Clean Room Solutions

Clean room applications impose particularly high requirements to the design of the chosen furnace. If the complete furnace is operated in a clean room an essential contamination of the clean room atmosphere must be avoided. Especially, the particle contamination must be reduced to a minimum.

The specific application determines the choice of the required furnace technology. In many cases forced convection furnaces are required to achieve the necessary temperature uniformity at lower temperatures. For higher temperatures, Nabertherm has also delivered many furnaces with radiant heating.

Furnace Installation in the Clean Room

If the complete furnace is supposed to be positioned in the clean room, then it is important that both the furnace chamber and the furnace housing as well as the controls provide for good protection against contamination. Surfaces must be easy to clean. The furnace chamber is tightly sealed to the insulation behind it.

If necessary, additional equipment such as filters for the fresh air supply or the air circulation in the furnace can be used to improve the cleanliness class. It is recommended to install the switchgear and the furnace controls outside the clean room.

Furnace Installation in the Grey Room, Furnace Charging from the Clean Room

Optimal results with respect to cleanness will be achieved by placing the furnace in the grey room with charging from the clean room. This significantly reduces the amount of costly space needed in the clean room to a minimum. The front and the furnace interior in the clean room are designed for easy cleaning. With this configuration even the highest clean room classes can be achieved.

Sluice Furnace between Grey Room and Clean Room

Logistics between clean room and grey room can often be easily sorted out. Lock furnaces with one door in the grey room and the other door in the clean room are the perfect choice for these applications. The inner chamber as well as the furnace front in the clean room will be especially designed for lowest particle contamination.

Please contact us if you are looking for a heat treatment solution under clean room conditions. We would be pleased to quote for the oven or furnace model that meets best your requirements.

The specific application determines the choice of the required furnace technology. In many cases forced convection furnaces are required to achieve the necessary temperature uniformity at lower temperatures. For higher temperatures, Nabertherm has also delivered many furnaces with radiant heating.

Furnace Installation in the Clean Room

If the complete furnace is supposed to be positioned in the clean room, then it is important that both the furnace chamber and the furnace housing as well as the controls provide for good protection against contamination. Surfaces must be easy to clean. The furnace chamber is tightly sealed to the insulation behind it.

If necessary, additional equipment such as filters for the fresh air supply or the air circulation in the furnace can be used to improve the cleanliness class. It is recommended to install the switchgear and the furnace controls outside the clean room.

Furnace Installation in the Grey Room, Furnace Charging from the Clean Room

Optimal results with respect to cleanness will be achieved by placing the furnace in the grey room with charging from the clean room. This significantly reduces the amount of costly space needed in the clean room to a minimum. The front and the furnace interior in the clean room are designed for easy cleaning. With this configuration even the highest clean room classes can be achieved.

Sluice Furnace between Grey Room and Clean Room

Logistics between clean room and grey room can often be easily sorted out. Lock furnaces with one door in the grey room and the other door in the clean room are the perfect choice for these applications. The inner chamber as well as the furnace front in the clean room will be especially designed for lowest particle contamination.

Please contact us if you are looking for a heat treatment solution under clean room conditions. We would be pleased to quote for the oven or furnace model that meets best your requirements.