High Temperature Furnaces

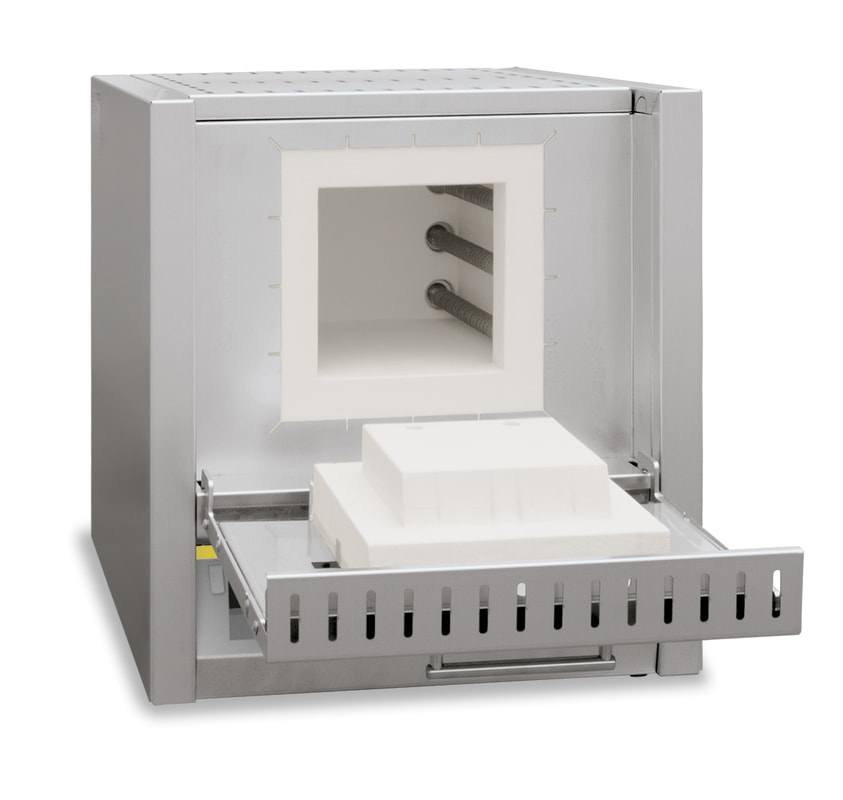

Nabertherm High Temperature Furnaces with SiC Rod Heating

These powerful laboratory muffle furnaces are available for temperatures up to 1400 °C, 1500 °C, 1550 °C or 1600 °C. The durability of the SiC rods in periodic use, in combination with their high heating speed, make these high-temperature furnaces to all-rounders in the laboratory. Heating times of 40 minutes to 1400 °C can be achieved, depending on the furnace model and the conditions of use.

Model |

Tmax °C |

Inner Dimensions in MM W x D x H |

Outer Dimensions in MM W x D x H |

Volume in l |

Minutes to Tmax |

HTC, HTCT 03/14 |

1400 |

120 x 210 x 120 |

415 x 545 x 490 |

3 |

40 |

HTC, HTCT 08/14 |

1400 |

170 x 290 x 170 |

490 x 625 x 540 |

8 |

40 |

HTC, HTCT 03/15 |

1500 |

120 x 210 x 120 |

415 x 545 x 490 |

3 |

50 |

HTC, HTCT 08/15 |

1500 |

170 x 290 x 170 |

490 x 625 x 540 |

8 |

50 |

HTCT 01/16 |

1550 |

110 x 120 x 120 |

340 x 300 x 460 |

1.5 |

40 |

HTC, HTCT 03/16 |

1600 |

120 x 210 x 120 |

415 x 545 x 490 |

3 |

60 |

HTC, HTCT 08/16 |

1600 |

170 x 290 x 170 |

490 x 625 x 540 |

8 |

60 |

Nabertherm High Temperature Furnaces with MoSi Heating Elements

Designed as tabletop models, these compact high-temperature furnaces have a variety of advantages. The rst-class workmanship using high-quality materials, combined with ease of operation, make these furnaces all-rounders in research and the laboratory. These high-temperature furnaces are also perfectly suited for the sintering of technical ceramics, such as zirconium oxide dental bridges.

Model |

Tmax °C |

Inner Dimensions in MM W x D x H |

Outer Dimensions in MM W x D x H |

Volume in l |

Minutes to Tmax |

LHT 02/16 |

1600 |

90 x 150 x 150 |

470 x 630 x 760 |

2 |

30 |

LHT 04/16 |

1600 |

150 x 150 x 150 |

470 x 630 x 760 |

4 |

25 |

LHT 08/16 |

1600 |

150 x 300 x 150 |

470 x 810 x 760 |

8 |

25 |

LHT 01/17 D |

1650 |

110 x 120 x 120 |

385 x 425 x 525 |

1 |

10 |

LHT 03/17 D |

1650 |

135 x 155 x 200 |

470 x 630 x 760 |

4 |

60 |

LHT 02/17 |

1750 |

90 x 150 x 150 |

470 x 630 x 760 |

2 |

60 |

LHT 04/17 |

1750 |

150 x 150 x 150 |

470 x 630 x 760 |

4 |

40 |

LHT 08/17 |

1750 |

150 x 300 x 150 |

470 x 810 x 760 |

8 |

40 |

LHT 02/18 |

1800 |

90 x 150 x 150 |

470 x 630 x 760 |

2 |

75 |

LHT 04/18 |

1800 |

150 x 150 x 150 |

470 x 630 x 760 |

4 |

60 |

LHT 08/18 |

1800 |

150 x 300 x 150 |

470 x 810 x 760 |

8 |

60 |

Nabertherm High Temperature Bottom Loading Furnace

The electrically driven lift-bottom considerably allows for proper charging of the high-temperature furnaces LHT/LB. The heating all around the cylindrical furnace chamber provides for an opitimal temperature uniformity. For high-temperature furnace LHT 02/17 LB the charge can be placed in charge saggars made of technical ceramics. Up to three charge saggars can be stacked on top of each other resulting in a high productivity. Due to its volume the high-temperature furnace LHT 16/17 LB can also be used for applications in production.

Model |

Tmax °C |

Inner Dimensions in MM Ø x H |

Outer Dimensions in MM W x D x H |

Volume in l |

LHT 02/17 LB |

1700 |

Ø 120 x 130 |

540 x 610 x 740 |

2 |

LHT 16/17 LB |

1700 |

Ø 260 x 260 |

650 x 1250 x 1980 |

16 |

Nabertherm High Temperature Furnace with Scale for Determination of Combustion Loss and Thermogravimetric Analysis (TGA)

These high-temperature furnaces were specially developed to determine combustion loss during annealing and for thermogravimetric analysis (TGA) in the lab. The complete system consists of the high-temperature furnace for 1600 °C or 1750 °C, a table frame, precision scale with feedthroughs into the furnace and powerful software for recording both the temperature curve and the weight loss over time.

Model |

Tmax °C |

Inner Dimensions in MM W x D x H |

Outer Dimensions in MM W x D x H |

Volume in l |

Minutes to Tmax |

LGT 04/16 SW |

1600 |

150 x 150 x 150 |

655 x 370 x 890 |

4 |

25 |

LHT 04/17 SW |

1750 |

150 x 150 x 150 |

655 x 370 x 890 |

4 |

40 |

Nabertherm High Temperature Furnaces with Molybdenum Disilicide Heating Elements with Fiber Isulation

Due to their solid construction and compact stand-alone design, these high-temperature furnaces are perfect for processes in the laboratory where the highest precision is needed. Oustanding temperature uniformity and practical details set unbeatable quality benchmarks. For con guration for your processes, these furnaces can be extended with extras from our extensive option list.

Model |

Tmax °C |

Inner Dimensions in MM W x D x H |

Outer Dimensions in MM W x D x H |

Volume in l |

HT 04/16 |

1600 |

150 x 150 x 150 |

730 x 490 x 1400 |

4 |

HT 08/16 |

1600 |

150 x 300 x 150 |

730 x 640 x 1400 |

8 |

HT 16/16 |

1600 |

200 x 300 x 260 |

810 x 700 x 1500 |

16 |

HT 40/16 |

1600 |

300 x 350 x 350 |

1000 x 800 x 1620 |

40 |

HT 64/16 |

1600 |

400 x 400 x 400 |

1130 x 900 x 1670 |

64 |

HT 128/16 |

1600 |

400 x 800 x 400 |

1130 x 1290 x 1670 |

128 |

HT 160/16 |

1600 |

500 x 550 x 550 |

1250 x 1050 x 1900 |

160 |

HT 276/16 |

1600 |

500 x 1000 x 550 |

1300 x 1600 x 1900 |

276 |

HT 450/16 |

1600 |

500 x 1150 x 780 |

1350 x 1740 x 2120 |

450 |

HT 04/17 |

1750 |

150 x 150 x 150 |

730 x 490 x 1400 |

4 |

HT 08/17 |

1750 |

150 x 300 x 150 |

730 x 640 x 1400 |

8 |

HT 16/17 |

1750 |

200 x 300 x 260 |

810 x 700 x 1500 |

16 |

HT 40/17 |

1750 |

300 x 350 x 350 |

1000 x 800 x 1620 |

40 |

HT 64/17 |

1750 |

400 x 400 x 400 |

1130 x 900 x 1670 |

64 |

HT 128/17 |

1750 |

400 x 800 x 400 |

1130 x 1290 x 1670 |

128 |

HT 160/17 |

1750 |

500 x 550 x 550 |

1250 x 1050 x 1900 |

160 |

HT 276/17 |

1750 |

500 x 1000 x 550 |

1300 x 1600 x 1900 |

276 |

HT 450/17 |

1750 |

500 x 1150 x 780 |

1350 x 1740 x 2120 |

450 |

HT 04/18 |

1800 |

150 x 150 x 150 |

730 x 490 x 1400 |

4 |

HT 08/18 |

1800 |

150 x 300 x 150 |

730 x 640 x 1400 |

8 |

HT 16/18 |

1800 |

200 x 300 x 260 |

810 x 700 x 1500 |

16 |

HT 40/18 |

1800 |

300 x 350 x 350 |

1000 x 800 x 1620 |

40 |

HT 64/18 |

1800 |

400 x 400 x 400 |

1130 x 900 x 1670 |

64 |

HT 128/18 |

1800 |

400 x 800 x 400 |

1130 x 1290 x 1670 |

128 |

HT 160/18 |

1800 |

500 x 550 x 550 |

1250 x 1050 x 1900 |

160 |

HT 276/18 |

1800 |

500 x 1000 x 550 |

1300 x 1600 x 1900 |

276 |

HT 450/18 |

1800 |

500 x 1150 x 780 |

1350 x 1740 x 2120 |

450 |

Nabertherm High Temperature Furnaces with SiC Rod

The high-temperature furnaces HTC 16/16 - HTC 450/16 are heated by vertically hung SiC rods, which makes them especially suitable for sintering processes up to a maximum operating temperature of 1550 °C. For some processes, e.g. for sintering zirconium oxide, the absence of interactivity between the charge and the SiC rods, these models are more suitable than the alternatives heated with molybdenum disilicide elements. The basic construction of these furnaces make them comparable with the already familiar models in the HT product line and they can be upgraded with the same additional equipment.

Model |

Tmax °C |

Inner Dimensions in MM W x D x H |

Outer Dimensions in MM W x D x H |

Volume in l |

HTC 16/16 |

1550 |

200 x 300 x 260 |

810 x 700 x 1500 |

16 |

HTC 40/16 |

1550 |

300 x 350 x 350 |

1000 x 800 x 1620 |

40 |

HTC 64/16 |

1550 |

400 x 400 x 400 |

1130 x 900 x 1670 |

64 |

HTC 128/16 |

1550 |

400 x 800 x 400 |

1130 x 1290 x 1670 |

128 |

HTC 160/16 |

1550 |

500 x 550 x 550 |

1250 x 1050 x 1900 |

160 |

HTC 276/16 |

1550 |

500 x 1000 x 550 |

1300 x 1600 x 1900 |

276 |

HTC 450/16 |

1550 |

500 x 1150 x 780 |

1350 x 1740 x 2120 |

450 |

Nabertherm High Temperature Furnaces with Molybdenum Discilicide Heating Elements with Refractory Brick Insulation

The high-temperature furnaces HFL 16/16 HFL 160/17 are characterized by their lining with robust light refractory bricks. This version is recommended for processes producing aggressive gases or acids, such as under glass melting.

Model |

Tmax °C |

Inner Dimensions in MM W x D x H |

Outer Dimensions in MM W x D x H |

Volume in l |

HFL 16/16 |

1600 |

200 x 300 x 260 |

1000 x 890 x 1620 |

16 |

HFL 40/16 |

1600 |

300 x 350 x 350 |

1130 x 915 x 1890 |

40 |

HFL 64/16 |

1600 |

400 x 400 x 400 |

1230 x 980 x 1940 |

64 |

HFL 160/16 |

1600 |

500 x 550 x 550 |

1400 x 1250 x 2100 |

160 |

HFL 16/17 |

1700 |

200 x 300 x 260 |

1000 x 890 x 1620 |

16 |

HFL 40/17 |

1700 |

300 x 350 x 350 |

1130 x 915 x 1890 |

40 |

HFL 64/17 |

1700 |

400 x 400 x 400 |

1230 x 980 x 1940 |

64 |

HFL 160/17 |

1700 |

500 x 550 x 550 |

1400 x 1250 x 2100 |

160 |