Carbon & Sulfur Analyzer

Introduction:

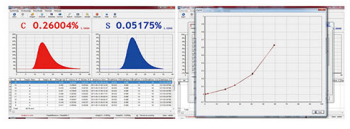

High-frequency Infrared Carbon & Sulfur Analyzer can determine the percentage of carbon and sulfur in steel, iron, alloy, nonferrous metal, cement, mineral, glass and other material.

High-frequency Infrared Carbon & Sulfur Analyzer can determine the percentage of carbon and sulfur in steel, iron, alloy, nonferrous metal, cement, mineral, glass and other material.

Technical Parameters:

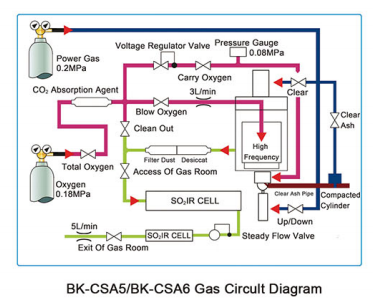

Working Principle |

High-frequency inductive combustion and infrared absorption system |

Sample Weight (Solid steel) |

Standard 0.5g |

Accuracy |

C/S: 0.1ppm |

Analysis Time |

20-100s adjustable (normally: 35s) |

Working Cycle |

24 hours |

The difference between BK-CSA5 and BK-CSA6:

Model |

BK-CSA5 |

BK-CSA6 |

Appearance |

Desktop detector, with desktop high frequency, furnace, save space |

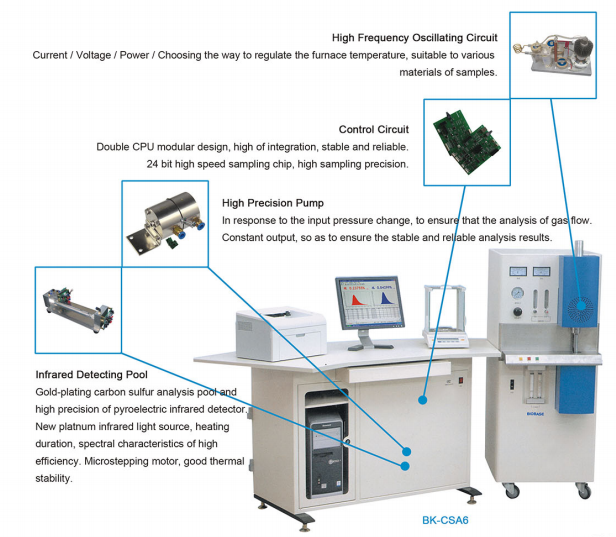

Separate workstation, with vertical high-frequency furnace |

Analysis Range |

C: 0.0005%-6.0000% (can be extended to 99.999%) S: 0.0005%-0.35000% (can be extended to 99.999%) |

C. 0.0001%-10.0000% (can be extended to 99.999%) S: 0.0001%-2.0000% (can be extended to 99.999%) |

Analysis Pool |

2 pools |

2 pools (optional 4 pools) |

Consumption |

2.2KW |

2.5KW |

Power Supply |

AC220V±10%, 50/60Hz |

AC220V±10%, 50/60Hz |

Package Size(W*D*H) |

1380*760*980mm |

1550*750*91 0mm, 740*580*1410mm |

Gross Weight |

200kg |

330kg |

Standard Accessories |

Main unit, high frequency automatic inductive combustion furnace, electric balance, computer, printer. 1000 times effective analysis of spare parts |

Main unit, high frequency automatic inductive combustion furnace, electric balance, computer, printer. 1000 times effective analysis of spare parts |