Ball Mill

Optional:

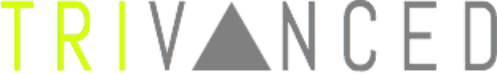

Selection of pot’s material: Pot’s material has no pollution to the grinding materials and no effect to the appearance of powder.

Selection of pot’s material: Pot’s material has no pollution to the grinding materials and no effect to the appearance of powder.

Technical Parameters:

Category & Request of Griding Material |

Reference for Mill Pots' Material Option |

Soil and other Materials which impurities are not allowed to be brought. |

Agate Pot |

Metal and non-metal materials which impurities are not allowed to be brought |

Zirconia Pot |

High hardness materials like diamond, hard alloy. |

Hard Alloy Pot |

Strong acid and strong alkali substances, and materials under high temperature. |

PTFE Mill Pot |

Iron and steel minerals, impurities are not highly sensitive materials. |

304 Stainless Steel |

Pigment material, and materials which can be processed at high temperature. |

Nylon Mill Pot |

Containing aluminum material like ceramic glaze. |

Corundum Pot |

Electronic material like lithium battery. |

Polyurethane Mill |

Easily oxidized materials which need to be protected by special gas. |

Vacuum Mill Pot |

Matching Ways for Mill Pots and Balls:

Agate Grinding Ball |

Zicronia Grinding Ball |

Tungsten Carbide Balls |

Stainless Stell Balls |

Alumina Balls |

Polyurethan Core Ball |

Steel Ball |

|

Agate MiII Pot |

▲ |

||||||

Zirconia Mill Pot |

▲ |

||||||

Hard Alloy Mill Pot |

▲ |

||||||

PTFE MiII Pot |

▲ |

||||||

Stainless Steel MiII Pot |

▲ |

||||||

Nylon MiII Pot |

▲ |

||||||

Corundum MiII Pot |

▲ |

|

|||||

Polyurethane MiII Pot |

▲ |

Remarks: ▲ Best Match

Best Match Ratio: Large-sized Ball: 20%; Medium-sized Ball: 50%; Small-sized Ball: 30%.

Best Match Ratio: Large-sized Ball: 20%; Medium-sized Ball: 50%; Small-sized Ball: 30%.

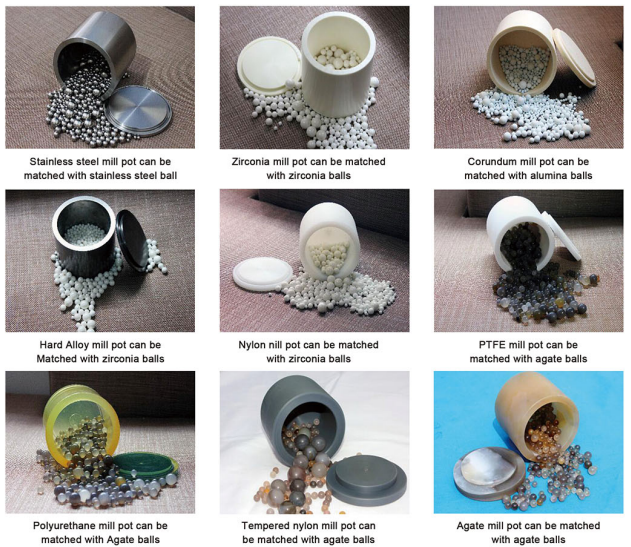

Vertical Planetary Ball Mill (Semi-Circle Type)

Application:

Planetary Ball Mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high-speed movement, and samples are eventually ground into powder. Various kinds of different materials can be ground by the mill with dry or wet method.

Minimum granularity of ground powder can be as small as 0.1µm

Planetary Ball Mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high-speed movement, and samples are eventually ground into powder. Various kinds of different materials can be ground by the mill with dry or wet method.

Minimum granularity of ground powder can be as small as 0.1µm

Technical Parameters:

Model |

BKBM-V0.4 |

BKBM-V2 |

Capacity |

0.4L |

2L |

Volume of Each Capacity |

50~100ml |

50~500ml |

Pot Quantity |

4 pcs |

4 pcs |

Running Time Range |

1~9999min |

1~9999min |

Reciprocal Running Time |

1~999min |

1~999min |

Adjustable Speed Revolution |

45~435rpm |

35~335rpm |

Rotation |

90~870rpm |

70~670rpm |

Noise |

≤58dB |

≤60dB |

Speed Control Mode |

Frequency Control |

Frequency Control |

Transmission Mode |

Gear Drive |

Gear Drive |

Working Mode |

2 or 4 pots can be used each time |

2 or 4 pots can be used each time |

Max Volume of Each Pot |

2/3 |

2/3 |

Feed Size |

Soft and Crispy material<10mm Other materials<3mm |

Soft and Crispy material<10mm Other materials<3mm |

Out-put Granularity |

Minimum Granularity can be reached to 0.1um |

Minimum Granularity can be reached to 0.1um |

Adjusting Mode of Rotate Speed |

Frequency converter with stepless speed regulation |

Frequency converter with stepless speed regulation |

Consumption |

0.25KW |

0.75KW |

Power Supply |

AC110/220V±10%, 50/60Hz |

AC110/220V±10%, 50/60Hz |

External Size(W*D*H)mm |

530*300*340 |

730*430*550 |

Package Size(W*D*H)mm |

595*360*485 |

820*530*720 |

Net Weight(kg) |

26 |

74 |

Gross Weight(kg) |

30 |

80 |

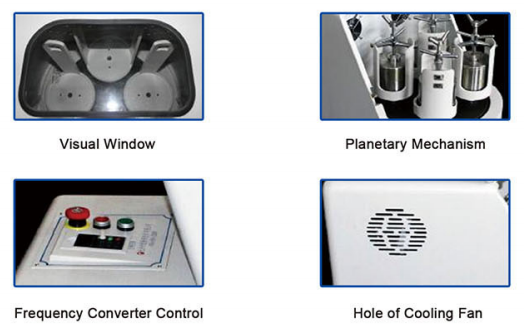

Vertical Planetary Ball Mill (Square Type)

Technical Parameters:

Model |

BKBM-V2S |

Capacity |

2L |

Volume of Each Capacity |

50~500mI |

Pot Quantity |

4pcs |

Running Time Range |

1~9999min |

Reciprocal Running Time |

1~999min |

Adjustable Speed Revolution |

35~335rpm |

Rotation |

70~670rpm |

Noise |

≤60dB |

Speed Control Mode |

Frequency Control |

Transmission Mode |

Gear Drive |

Working Mode |

2 or 4 pots can be used each time |

Max Volume of Each Pot |

2/3 |

Feed Size |

Soft and Crispy material<10mm, Other materials<3mm |

Out-put Granularity |

Minimum Granularity can be reached to 0.1um |

Adjusting Mode of Rotate Speed |

Frequency converter with stepless speed regulation |

Consumption |

0.75KW |

Power Supply |

AC110/220V±10%, 50/60Hz |

External Size(W*D*H)mm |

770*470*570 |

Package Size(W*D*H)mm |

820*540*680 |

Net Weight(kg) |

93 |

Gross Weight(kg) |

98 |

Light Horizontal Planetary Ball Mill

Technical Parameters:

Model |

BKBM-H2L |

Capacity |

2L |

Volume of Each Capacity |

50~500ml |

Pot Quantity |

4 pcs |

Running Time Range |

1~9999min |

Reciprocal Running Time |

1~999min |

Adjustable Speed Revolution |

35~335rpm |

Rotation |

70-670rpm |

Noise |

≤60dB |

Transmission Mode |

Gear Drive |

Working Mode |

2 or 4 pots can be used each time |

Max Volume of Each Pot |

2/3 |

Feed Size |

Soft and Crispy material<10mm, Other materials<3mm |

Out-put Granularity |

Minimum Granularity can be reached to 0.1pm |

Adjusting Mode of Rotate Speed |

Frequency convener with stepless speed regulation |

Speed Control Mode |

Frequency Control |

Consumption |

0.75KW |

Power Supply |

AC110/220V±10%, 50/60Hz |

External Size(W*D*H)mm |

700*570*520 |

Package Size(W*D*H)mm |

800*610*670 |

Net Weight(kg) |

105 |

Gross Weight(kg) |

123 |